Introduction

In business, uncertainty is the enemy. It leads to unexpected downtime, costly mistakes, and missed opportunities. But what if you had a tool that could fight Doubt? A tool that let you test a change before you commit, fix a machine before it breaks, and see the future of your operations?

That tool is a Digital twin. While the technology is complex, the business value of a digital twin is remarkably simple: it replaces guesswork with data-driven certainty. It’s not just about creating a cool 3D model; it’s about unlocking tangible, measurable results. Let’s move beyond the hype and explore the seven core benefits of digital twin technology that deliver real ROI.

Table of Contents

Key Takeaways

The primary benefits of digital twin technology revolve around creating value and reducing risk. The top advantages include:

- Massive Cost Savings: From reduced maintenance expenses to optimized resource use.

- Increased Efficiency: Streamline processes by identifying and eliminating bottlenecks.

- Predictive Maintenance: Fix problems before they happen, eliminating unplanned downtime.

- Improved Safety: Simulate hazardous scenarios and train personnel in a risk-free environment.

- Faster Innovation: Accelerate R&D by testing virtual prototypes instead of physical ones.

Benefit 1: Drastically Reduce Operational Costs

This is often the first and most compelling digital twin ROI driver. By creating a living model of your assets, you gain unprecedented visibility into where every dollar is going.

- How it works: The twin analyzes real-time data on energy consumption, material usage, and asset performance.

- Digital Twin Example: A factory manager uses a System Twin of their production line to discover that one specific machine is consuming 30% more energy than its peers. By identifying and fixing the inefficient machine, they achieve significant digital twin cost savings on their monthly utility bills.

Benefit 2: Eliminate Unplanned Downtime with Predictive Maintenance

Unplanned downtime is a silent killer of profitability. A digital twin acts as a crystal ball for your equipment.

- How it works: AI within the twin’s analytics engine analyzes data for subtle patterns—like temperature fluctuations or vibration anomalies—that precede a failure.

- Digital Twin Example: A wind farm operator receives an alert from a turbine’s digital twin: “Warning: Gearbox bearing #3 shows a vibration pattern consistent with 95% probability of failure within 150 hours.” They can schedule maintenance during a low-wind period, ordering the exact part they need in advance and avoiding a catastrophic, expensive failure.

Benefit 3: Enhance Worker Safety and Training

Some operational scenarios are too dangerous to test in the real world. A digital twin provides a safe, virtual sandbox.

- How it works: You can simulate hazardous events (like a chemical spill or equipment malfunction) or complex procedures without any physical risk.

- Digital Twin Example: An energy company trains its new field operators on how to handle a high-pressure valve failure. The operators use a VR interface to interact with the digital twin, learning the exact sequence of steps in a realistic but 100% safe environment.

Benefit 4: Accelerate Product Innovation and R&D

Why build ten expensive physical prototypes when you can build a thousand virtual ones for a fraction of the cost?

- How it works: Engineers can design, build, and test new products in a virtual environment. They can subject a virtual prototype to extreme conditions to find its breaking point.

- Digital Twin Example: An automotive company designs a new electric motor. Using its digital twin, they simulate 10 years of wear and tear in just 48 hours, identify a weak point in the design, and reinforce it—all before a single piece of metal has been machined.

Benefit 5: Boost Efficiency by Optimizing Processes

Every business process has hidden bottlenecks. A digital twin shines a powerful light on them.

- How it works: By creating a twin of an entire system (like a warehouse), you can see how different assets and people interact.

- Digital Twin Example: An e-commerce giant creates a digital twin of its fulfillment center. They discover that the routes their picking robots take are causing traffic jams in two specific aisles. They simulate a new routing algorithm in the twin, see a 20% improvement in picking speed, and then deploy it to the physical fleet.

Benefit 6: Improve Decision-Making with Data-Driven Insights

Strategic decisions are often based on historical data and educated guesses. Digital twins provide a live, dynamic view of the business.

- How it works: By combining operational data with business data (like supply chain costs or customer demand), executives can ask complex “what-if” questions.

- Digital Twin Example: A CEO considering a merger can use an Ecosystem Twin to model how combining two different supply chains would impact costs and delivery times, providing crucial data for negotiations. As industry experts like McKinsey note, this level of insight is transformative.

Benefit 7: Enhance Sustainability and Reduce Carbon Footprint

One of the most powerful modern advantages of digital twins is their ability to drive green initiatives.

- How it works: By optimizing energy consumption, reducing material waste, and streamlining logistics, digital twins naturally lead to a more sustainable operation.

- Digital Twin Example: A commercial real estate firm uses a digital twin of its office building to optimize the HVAC and lighting systems in real-time based on occupancy and weather forecasts, reducing the building’s energy consumption by 25%.

Conclusion: From Technical Tool to Business Imperative

The benefits of digital twin technology are clear, compelling, and far-reaching. This is no longer a niche technology for engineers; it is a strategic tool for the entire C-suite. By providing a direct line of sight into your operations and a clear path to digital twin ROI, it offers a powerful way to reduce costs, mitigate risk, and build a more efficient, resilient, and sustainable business for the future.

Read More:

- 7 Key Benefits of Digital Twin Technology (2025 ROI Guide)

- The 5 Key Components of a Digital Twin: A Breakdown of the Technology

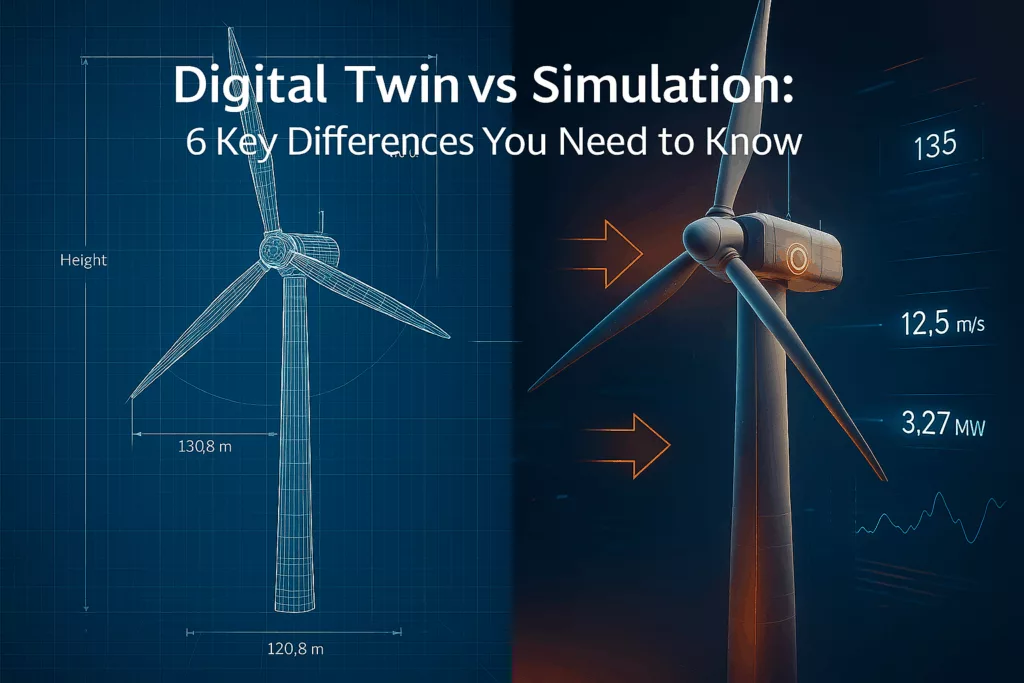

- Digital Twin vs Simulation: Key Differences for Industry 4.0 (2025 Guide)

- what is digital twin technology – how, why, and when to use it

Frequently Asked Questions (FAQ)

What is the single biggest benefit of digital twin technology?

While it varies by industry, the most universally cited benefit is Predictive Maintenance. The ability to prevent unplanned downtime provides an immediate and easily measurable return on investment for almost any business that relies on physical equipment.

Are these benefits only for large corporations?

Not anymore. While large enterprises were the early adopters, the rise of cloud computing and more affordable IoT sensors has made digital twins accessible to small and medium-sized businesses (SMBs). An SMB can start by creating an Asset Twin of their single most critical machine to realize significant ROI.

How long does it take to see a return on investment (ROI)?

The timeline for digital twin ROI depends on the project’s scope. A focused predictive maintenance project on a critical asset can show a positive return in as little as 6-12 months by preventing just one major outage. Larger System or Ecosystem twins are longer-term strategic investments.

Hi, just wanted to tell you, I liked this article. It was inspiring. Keep on posting!