If you are a business owner who wants to keep ahead of the competition, you have probably heard of digital twins and their powerful digital twin applications.

These virtual duplicates of actual systems are revolutionizing industries by providing real-time monitoring, predictive insights, and sophisticated optimization capabilities. If the term seems daunting, don’t worry—you’re not alone! In this article, I will go over the fundamentals of digital twins, why they are important for your business, and how you can begin using them to improve your operations. Let’s dive in!

Digital twins are among the most transformative technologies in modern industry. But what exactly is a digital twin, and why does it matter for your business? More importantly, how can it help you stay ahead of the competition?

What is a Digital Twin?

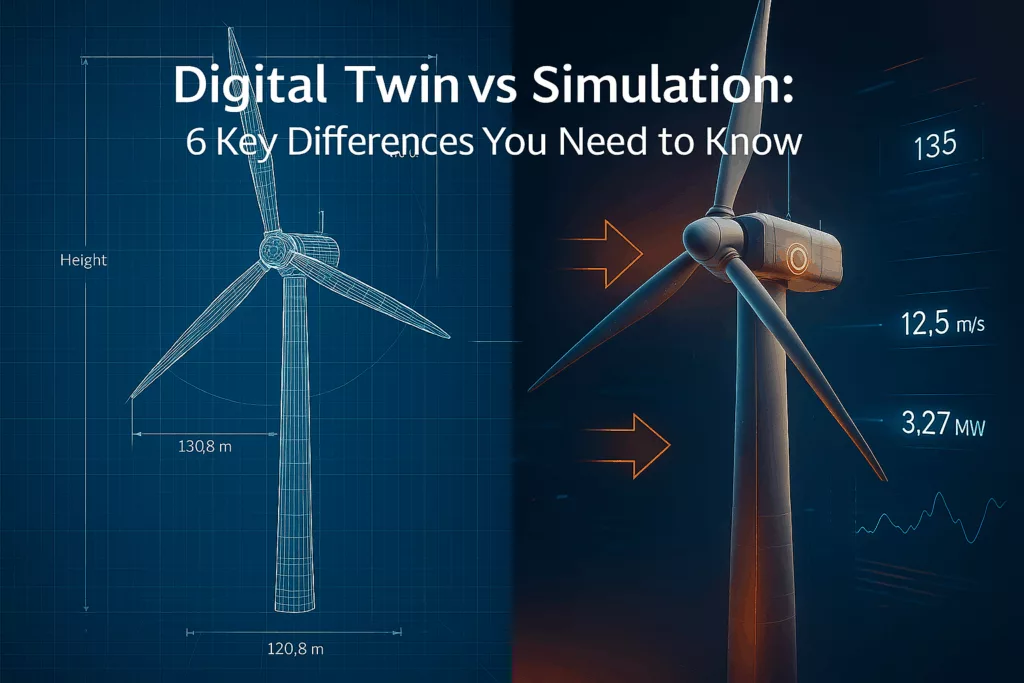

A digital twin is a virtual representation of a physical object, process, or system. In essence, it uses data and technology to mimic its real-world counterpart, enabling simulation, analysis, and optimization.

You may be thinking, “Why should I care about something so abstract?” Here’s the deal: digital twins are no longer just theoretical concepts. They are becoming a crucial component of firms’ digital transformation initiatives, allowing them to reduce costs, streamline operations, and improve customer experiences.

How Digital Twin Technology Has Evolved

The Early Days of Digital Twins

The concept of digital twins actually goes back a few decades, but it was primarily used in NASA’s space program to monitor spacecraft. Back then, they were simple simulations. Fast forward to today, and digital twins are much more sophisticated thanks to the integration of IoT (Internet of Things), AI (artificial intelligence), and cloud computing.

In the beginning, digital twins were mostly used in manufacturing for asset management and predictive maintenance. However, as technology advanced, businesses such as healthcare, retail, and even energy management recognized the value of these digital copies.

The Key Components of a Digital Twin

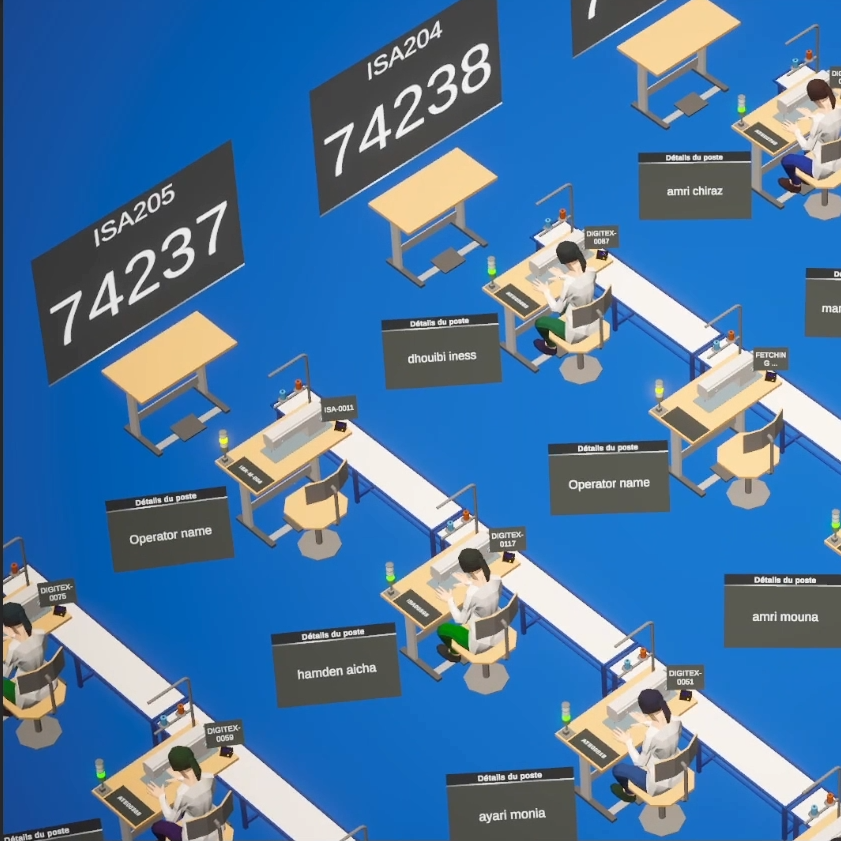

Digital twins collect data from sensors or IoT devices connected to the physical object. Then, this data is used to create an accurate virtual model. With this model, businesses can use advanced analytics and simulations to predict outcomes, prevent issues, and make informed decisions.

Physical Asset

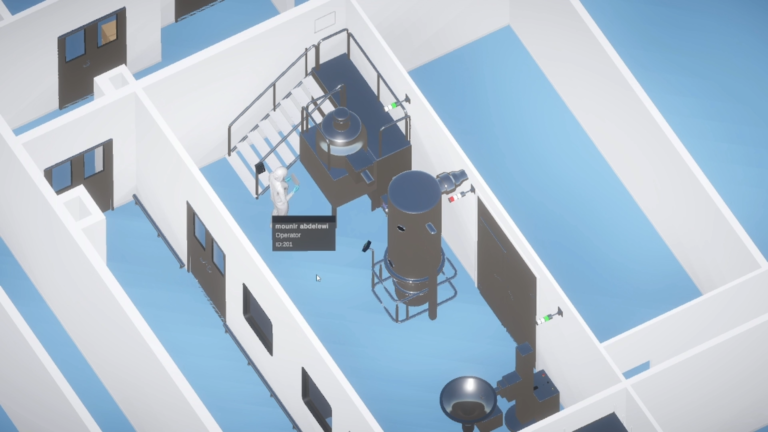

This is the real-world object or system that the digital twin will replicate. It could be anything from a manufacturing machine to a building, a vehicle, or even a person’s health data.

Digital Representation

This is where the magic happens. The digital twin is the virtual model that mirrors the physical asset. It collects data from sensors, often installed on the asset itself, to reflect its real-time status.

Data Analytics & AI

The data gathered from the physical asset is analyzed using advanced algorithms, AI, and machine learning. This allows businesses to gain insights, make predictions, and optimize performance. Think of it like a crystal ball—but grounded in real-time data.

Simulation & Monitoring

Digital twins aren’t just passive models. They’re active systems that allow businesses to simulate scenarios and monitor asset performance continuously. For example, a factory can simulate how a new production line would impact throughput or a car manufacturer can test the performance of a new vehicle design virtually before it hits the road.

Practical Digital Twin Applications for Business Owners

So, how does this all apply to your business? Digital twins can have a huge impact across various industries. Let’s look at a few practical applications.

Digital Twin Applications in Predictive Maintenance

For instance, predictive maintenance is one of the key benefits. It helps businesses identify and fix problems before they occur, saving time and money. In addition, operational efficiency improves as businesses optimize processes in real-time. Moreover, digital twins enhance product innovation by enabling virtual prototyping.

Process Optimization as a Digital Twin Application

Imagine being able to streamline your entire business workflow, whether it’s in manufacturing, supply chain management, or even customer service. Digital twins make this possible by allowing you to simulate different scenarios. For example, you could test how a new inventory system would perform without making any physical changes to your warehouse.

I recall a conversation I had with a warehouse manager who wanted to optimize their storage space. With a digital twin of their warehouse, they were able to simulate different shelf arrangements, track the flow of goods.

Digital Twin Applications for Product Lifecycle Management

For product manufacturers, digital twins provide incredible insight into the entire lifecycle of a product—from design to production to maintenance. These digital models can help with quality control, design improvements, and customer satisfaction.

The Business Benefits of Digital Twins

Now that we’ve seen the how and the why, let’s talk about the business benefits that come with adopting digital twins.

Cost Reduction

Implementing a digital twin allows you to reduce costs across various areas of your business. From minimizing machine downtime to optimizing energy consumption, digital twins help lower operational expenses. They also make it easier to predict when a product or asset will require maintenance, saving you from costly emergency fixes.

Improved Decision-Making

Digital twins provide real-time, data-driven insights that lead to better decision-making. Whether it’s a supply chain manager deciding when to reorder materials or a CEO forecasting market trends, digital twins provide the data necessary to make smarter decisions faster.

A Competitive Edge

In today’s fast-paced market, staying ahead of the competition is crucial. Companies leveraging digital twins have a significant edge because they can quickly adapt to changes, predict potential issues, and optimize operations—all in real-time.

Challenges in Implementing Digital Twins

While digital twins are incredibly powerful, they’re not without their challenges. Here are a few hurdles you might face when considering adoption.

Initial Investment

Setting up digital twin technology can require a significant upfront investment, especially if you need to purchase new sensors or update existing systems. However, as the technology matures, the costs are dropping, and the ROI is becoming increasingly clear. Businesses that invest now can expect long-term gains.

Data Security

With so much data being collected and transmitted, it’s crucial to ensure that your systems are secure. Cybersecurity is a major concern for any digital system, and digital twins are no exception. Ensuring that data is encrypted and following industry regulations will help mitigate risks.

Integration Complexity

For many businesses, integrating digital twins with existing systems can be challenging. This is especially true if you’re working with legacy equipment or outdated IT infrastructure. Many digital twin platforms are designed to integrate seamlessly with modern systems, making the transition smoother.

How to Get Started with Digital Twins

To get started, assess your business needs and identify processes where digital twins can make the biggest impact. Next, collaborate with experts to design a solution tailored to your goals. After that, begin with small pilot projects and scale up as you see results.

Step 1: Identify Key Areas for Implementation

The first step is to identify where digital twins can provide the most value in your organization. Is it predictive maintenance? Process optimization? Energy management? Start small with one project that aligns with your business goals.

Step 2: Choose the Right Technology

There are many digital twin platforms out there, so it’s essential to choose one that fits your business needs. Some are focused on manufacturing, while others cater to logistics, healthcare, or smart city applications. Do your research, and consider working with a consultant to make sure you’re selecting the best solution.

Step 3: Start Small and Scale Gradually

I always recommend starting with a pilot project. Pick a single asset or process to create a digital twin of, then scale from there as you see success. This helps you understand the system’s potential without making a massive upfront investment.

Conclusion: Embrace the Future with Digital Twins

Digital twins are no longer just a concept for tech giants—they’re a practical tool for businesses of all sizes. By providing real-time insights, predictive analytics, and operational optimization, digital twins can help businesses reduce costs, improve efficiency, and stay ahead of the competition.

The future is digital, and digital twins are leading the charge. Are you ready to harness their potential? Let’s bring your vision to life. Contact us today to learn how digital twins can transform your business!

Hello! I hope you’re having a great day. Good luck 🙂

Hi, Thank you.

hi

Hi Tommy

Pingback: Digital Twin vs Simulation: 6 Essential Differences You Can't Ignore

Pingback: The 5 Key Components of a Digital Twin: An Ultimate Guide

Pingback: 7 Key Benefits of Digital Twin Technology (2025 ROI Guide)